Thermal Cleaning

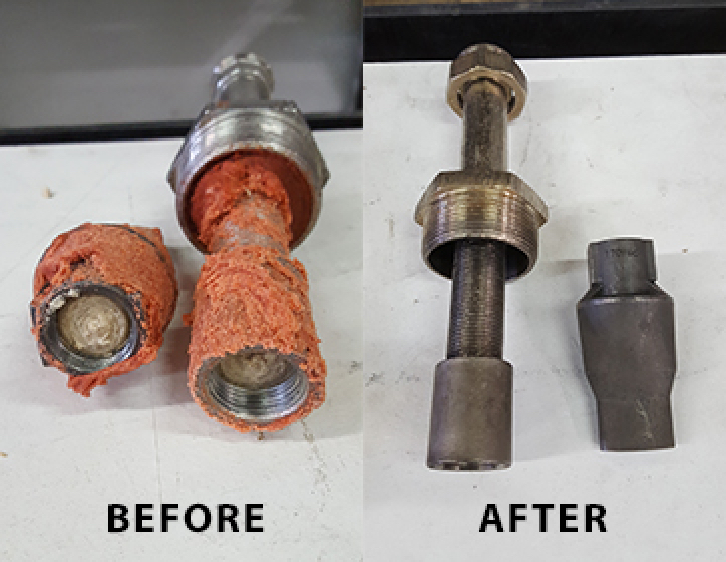

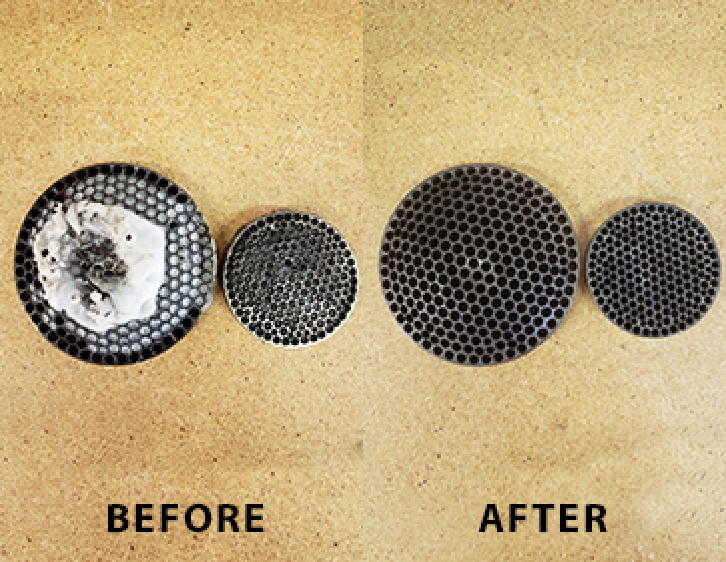

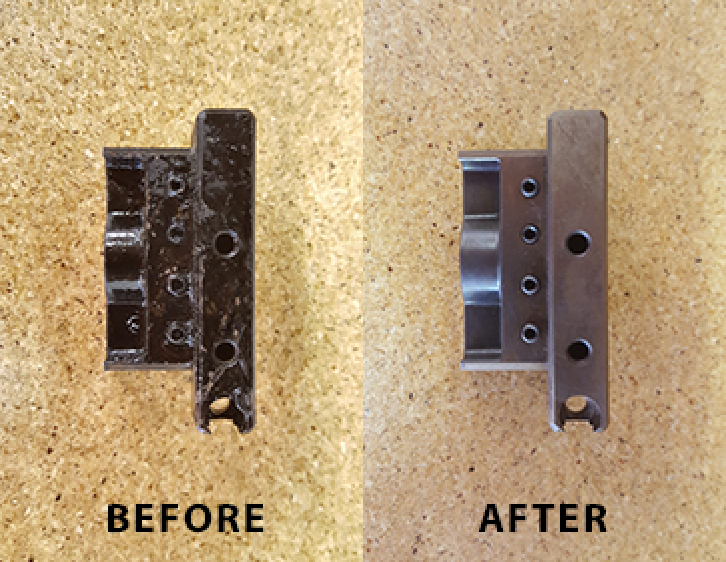

Accurate Thermal Systems fluidized baths clean metal parts by thermally removing all types of organic material, including plastic, paint, resin, adhesive, glue, oil, silicone, rubber, grease, food, and plant-based products. Fluidized baths offer a fast, safe, and efficient method to clean extrusion and injection molding parts. Fluidized baths are not grit or media blasters; they thermally burn off all organic material from metal parts and tooling.

Our fluidized baths can be used to clean breaker plates, dies, injection nozzles, feed screws, hot runner parts, nozzles, die plates, extrusion profiles, screen changers, barrels, hooks, spin packs, tips, feed pipes, film extrusion dies, screw elements, molds, spinneret, hardware, pressure transducers, melt flow indexer dies, capillary rheometer parts, crossheads, die adaptor, screen pack, nuts and bolts, profile extrusion dies and many more types of parts.

The thermal cleaning process typically takes 30 to 60 minutes to remove all material from the tooling. A fast and efficient cleaning cycle minimizes downtime during line change-outs and maintenance. The fluidized bath cleaning process does not require the operator’s assistance after the part is placed into the bath, allowing them to move on to other duties. Fluidized baths are four to five times faster and more energy efficient than pyrolysis, burn-out, and pyrolytic burn-off ovens. Unlike ultrasonic cleaners and chemical purging, fluidized baths require no hazardous chemicals. Any emissions generated by all thermal cleaning processes can be vented into plant exhaust or can be completely removed with one of our HEPA air filtration systems or thermal afterburner. The burned-off organics are carried into the aluminum oxide as carbon and residue. Used aluminum oxide can be disposed of in a landfill or regular trash.

The fluidized bath cleaning process thermally breaks down material on the inside of assembled tools, allowing easy disassembly. Unlike torches, ovens, or hand-cleaning methods, stable temperatures and a fluidized bath’s uniform heat distribution eliminate tool damage and distortion.

We recommend the Accurate Thermal Systems models FTBSL6, FTBLL12, FTBLL12W, FTBLL26, FTBLL27 & FTBLL47 for these cleaning applications.

Thermal Cleaning in Action

Why choose a fluidized bath over other cleaning methods?

- Fast removal of organics from tooling, parts, and hardware in under 60 minutes, unlike 4 to 8 hours with burn-off and pyrolysis ovens

- Thermal cleaning is the most labor-efficient method to clean tooling requires only 5 to 10 minutes per hour of labor for the cleaning process

- Unlike ultrasonic cleaning, no unsafe and hard-to-dispose chemicals or harsh solvents are needed

- Unlike torching, drilling, scraping, knives, lathes, and wire wheels, thermal cleaning does not damage expensive tooling

- Breaks down and removes organic-based material from small holes, orifices, channels, profiles, and openings down to 0.010″

- Fluidizing action is gentle and will not abrade or change the surface finish of tooling and parts

- Complements other cleaning systems and speeds up line change-outs to minimize production downtime

- Removes all types of plastic and elastomers, including fluoropolymers, rubber, and silicone

Complimentary Sample Cleaning

Send us an example of your tooling for a complimentary cleaning! We’ll perform a sample cleaning, produce a video of your part being cleaned, and ship it back within two days of receipt.