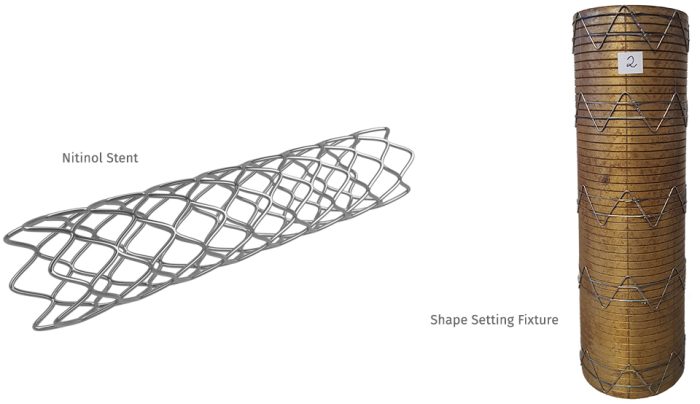

Nitinol Shape Setting and Heat Treatment

Accurate Thermal Systems, a leader in medical device shape setting technology, offers several models of fluidized baths that provide very stable and uniform temperature environments for nitinol shape setting, heat treatment, annealing, tempering, thermal stress analysis, and heat setting of various metal components, parts, and assemblies. Our larger fluidized baths are ideal for volume production runs of material, and our smaller benchtop system is ideal for research and development work and small batch analysis.

Some of the key applications are shape-setting nitinol stents, heat-setting medical devices, heat treatment and annealing of platinum and stainless steel guide wires, nitinol assemblies, tool cleaning for extruded medical products, and any other temperature applications that require the utmost stability and uniformity at temperatures up to 605°C. For these applications, we recommend fluidized bath models FTBSL6, FTBSL15, and FTBSL25.

Fluidized baths offer excellent heat transfer due to the liquid-like properties of aluminum oxide that allow heat soak and overall manufacturing time to be minimized with predictable results. Fluidized aluminum oxide provides fast heat-up of immersed parts and objects three to four times faster than an oven without the required post-processing cleaning and safety concerns of molten salt baths. Accuthermal fluidized baths can be operated with an inert gas such as argon or nitrogen to reduce oxidation.

We also offer customized fluidized bath units that operate up to 800°C and 1000°C should your heat treatment application require higher operating temperatures. Each custom fluidized bath is designed and manufactured to meet your specific requirements, including any accessories. Please contact us for more information.

All Accurate Thermal Systems FTBSL fluidized bath models use a unique bath cover and lid combination that provides full access to the bath while minimizing heat loss and blocking media from leaving the system. This results in a cleaner work environment with minimal dusting than other inferior fluidized baths.

The bath cover and lid included on our model FTBSL15 have a working diameter of 7.3″ and a depth of 15″, and a working diameter of 7.3″ and a depth of 25″ for model FTBSL25. The included lid with handle can be modified by the customer to suspend devices and fixtures for immersion into the bath. The lid can also be modified to include a thermowell for placing temperature sensors for calibration applications.

Features & Benefits

- Fully automatic fluidizing air control

- Advanced PID temperature controller

- Over-temperature limit protection

- RS485 computer interface

- Windows PC scheduler software*

- Bath cover and lid system to retain heat and media

- Customizable lid can be modified to suspend devices and mandrels into the bath

- No jars to empty or dust extraction required, much safer than salt baths

*Can be used to set the bath to reach operating temperatures and to cool down to safe temperatures according to your work schedule.

Temperature Validation Software (TVS) for Fluidized Temperature Baths

The Temperature Validation Software (ATS3111) allows remote control of the fluidized bath and temperature data collection for process and operation validation to meet quality and independent agency requirements.

Customers Using Our Shape Setting and Heat Treatment Systems

Complimentary Heat Treatment

Send us an example of your device or fixture for a complimentary heat treatment! We’ll perform the heat treatment, produce a video of your part being cleaned, and ship it back within two to three days of receipt.